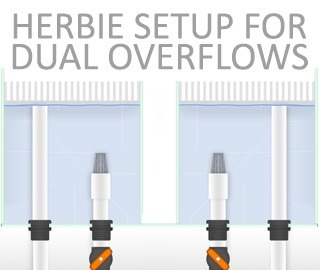

Herbie method for Dual Overflows

Tanks with 2 overflows can be set up for a siphon-based drain method like the Herbie or Bean design. There are essentially three ways to do it correctly, and one way to avoid. A few... more

Reef Aquarium Plumbing & Design