Plumbing a reef tank is something that might sound harder than it is. Even if you’ve never done much DIY work before, you can do this.

Here is what to know about how to measure, cut and glue your plumbing. Some basic info about what materials to select is in here as well.

Choice of Piping Material

The most common choice for plumbing is PVC – a time-tested material that is both cheap and easy to find at hardware stores in various sizes.

Info about how to choose pipe material is presented on Suitable Pipe Materials for Plumbing Reef Aquariums

Where to use Rigid vs. Flexible?

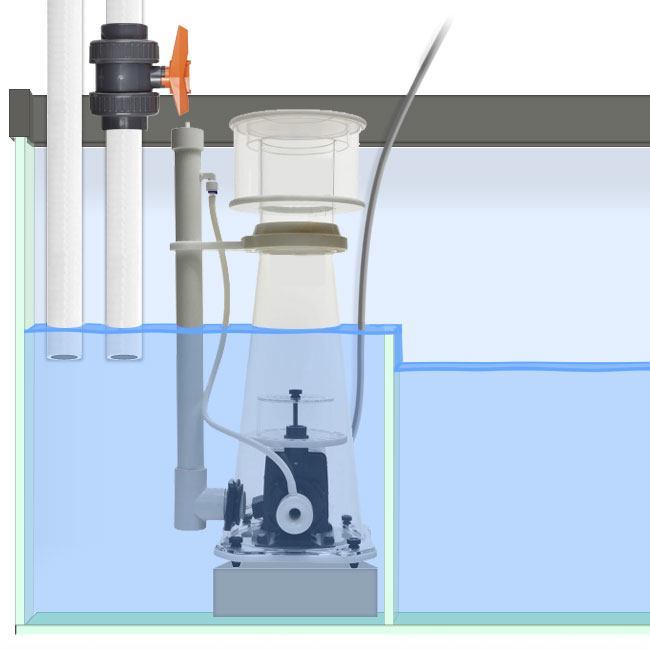

For overflow standpipes, rigid tubing should be used. Other than that, flexible tubing can be used throughout. Flex tubing will lessen any horizontal runs, which is beneficial for siphon based overflow methods like the Herbie Overflow.

Cutting PVC

The easiest way to cut all types of PVC and other tubing is with a ratcheting PVC cutter. This handheld tool is quick and results in nice, square cuts with no dust up to about 1-1/4″ pipe. For larger diameters, wood saws such as a miter saw must be used. A normal wood cutting blade does the job. Be aware of where the blade is oriented and where it will shoot the dust. Be sure to wear eye protection because of the plastic dust or shrapnel. A full-face shield is better.

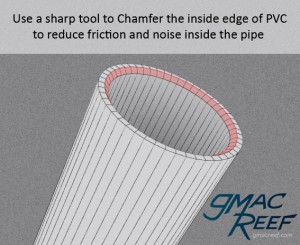

Care should be taken when cutting pipe with any kind of power tool. Supporting the piece can be a challenge so get a helper to hold as well while you make your cut. Remove any burrs before you glue anything.

Test fitting

Going with “Measure twice, cut once” you should assemble your plumbing before doing any gluing. This will reduce do-overs and trips back to the store. It’s also helpful to mark the orientation of the fittings with a Sharpie so they line up at the proper angle when you glue them. While fittings are supposed to be universal, you will find small differences in pieces from different manufacturers.

Gluing PVC

Gluing should ideally be done in a well-ventilated area over a drop cloth of some kind. The term “Gluing” is used only to describe the process, as you are really using a solvent cement to chemically bond the two pieces of PVC together. The bond that is created is completely permanent, and pieces will have to be cut or sawn apart.

You may want to practice with a few test pieces to get a good connection without using too much Cement. If you use too much primer or cement, it can result in messy drips and runs all over the pipes that can look ugly. Here is a good video on how to make a connection:

For the cement, there are clear types but the most common variety is dark gray in color. An advantage of the dark gray glue solvent is that it makes it easier to visually confirm you’ve applied it to the pieces completely before assembly.

What type of Bulkheads should I use?

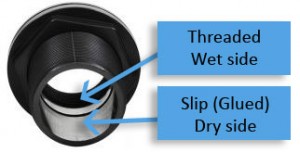

The Bulkheads I typically use are called “Bulkhead ABS Thread x Slip (Thread on the Flange/Head side)”

The Bulkheads I typically use are called “Bulkhead ABS Thread x Slip (Thread on the Flange/Head side)”

These are a good choice for the Herbie System. Threaded fittings (like standpipes) can be installed in the tank to the flange side of the bulkhead, and the outside end glues to a piece of PVC for a secure, permanent connection.

Threaded Fittings

These fittings are self explanatory but there are some things to be aware of. You should not use Teflon tape as it is intended for metal. Using it with PVC will usually result in an inferior seal. Threads can vary by manufacturer and also by Schedule (ex. 40 vs. 80). Threaded fitting like unions generally should be tightened to finger-tight, then 1 to 2 turns more. This can generally be done without any tools. You should not use any kind of glue or paste. The only suitable thing to use on the threads is non-hardening thread sealant. Most people don’t use anything.

Drilling Glass

With the proper bit, this is quite easy to do. Take your time, make sure the bit is lubricated with water, and let the bit do the work, not the pressure of the drill.

After several questions about drilling glass, I decided to expand this info on how to set up and make the holes. Drilling Aquarium Tanks with a Diamond Glass Hole Bit

This video shows the basic process but you really shouldn’t rush drilling for a few reasons.

Installing Bulkheads

Bulkheads come ready to install and don’t require any extra glue, etc. but some people add a lubricant to the rubber gasket. This generally isn’t needed. The only type suitable is a silicone based type – Never use any kind of petroleum based oil on the gasket.

How to Install: The gasket should be placed between the flange and the glass on the inside of the tank. You generally want to tighten the Nut to the point of contact, then go 3/4 of a turn past that point using a wrench if possible. Do not over-tighten, because the glass will crack. Once tight, it may be possible to spin the Bulkhead in the hole by forcing it, even though the seal is intact.

It is important to understand that when you drill holes in a piece of glass, the holes become a point where force concentrates.

The places where holes are drilled in a pane of glass, even with bulkheads installed, can become an Achilles’ Heel of the tank.

This just means that you should be careful with your tank, especially around the bulkheads.

Practical ways to protect your tank

- Never allow the tank to rest with any part of its weight on a Bulkhead such as during moving. Remove the bulkheads first or support the tank otherwise.

- Take care not to pull, bump or place any force on the standpipes in an overflow for example.

- Leverage and forces on bulkheads are more pronounced with Rigid PVC. Flexible PVC or “Spa-flex” will absorb some force but still has the potential to stress bulkheads and glass

- Supporting plumbing by attaching it to your stand with brackets is a good idea

These forces are also why adding bulkheads to any tank with glass thickness less than 6mm (1/4″) is a bad idea. Anything thinner simply does not have enough strength to stand up to normal amounts of force.

Gluing pipe to Bulkheads

Most (if not all) Bulkheads you will find are made from black ABS, not PVC. It is generally not advisable to join ABS to PVC using regular PVC cement, but I have done so many times. Never had a problem. There is a special cement for PVC to ABS connections that you can find if you are concerned.

On the dry side of the bulkhead, you may want to glue a short length of PVC (3-4″) to it. Then, glue a union to this short piece. Using a union here makes it easy to disconnect your drain hoses if you need to move the tank. Keep in mind that this will be semi-permanent, and the only way to actually remove the bulkhead will be to saw through the short length of PVC.

Leak test

It’s a good idea to test your system for any leaks by filling it with tap water then turning the return pump on. Before this, You can use an air compressor to blast air through the pipes to get rid of most of the shavings or sawdust that might be in there.

Observe the system again after a few hours to confirm all glued and threaded connections are secure and leak-free. You should also shut off the return pump to test the overflow and that you have enough sump capacity. With the return pump off, you can also mark the high-water point in the return pump sump chamber to tell you what the max-water level should be.

Doing a leak test helps flush out the system before you add your rock, fish and sand.

It’s been suggested that silicone grease or Teflon tape be used on the threaded connections to the bulkheads inside the overflow as a way to prevent the threads from getting “locked” due to calcium carbonate build-up. Thoughts?

My advice regarding threaded fittings is to avoid them if possible, because they are not as impermeable as a glued slip connection. You can generally plumb a tank without any threaded fittings. The exception would be the bulkheads I suggest people use are threaded on the flange / inside the tank side, which allows for standpipes to be unscrewed. There is no risk of leaking inside the overflows.

Getting calcium buildup in the threads sounds like a hypothetical “what if”. I have never seen this happen. Even if some water seeps into the threads a little, it won’t create deposits like fast-flowing water sometimes can around valves for instance.

The only sealant that is suitable for PVC and made for it is non-hardening thread sealant. Teflon is actually made for metal threads and is not necessary, although a lot of people use it.

Using a lubricant on the threads can make it easy to over-tighten. I added a good link to the post with more info. Thanks for commenting.

Hello, I am confused as every article I have read on tightening bulk heads say to go 1/4 turn beyond hand tight. You state 3/4 turn. Can you please clarify this. Thank you.

Not beyond hand tight, beyond the point of 1st contact. Start measuring when the nut touches the glass. A wrench should only need to be used for about the last 1/4 of a turn or so.