Turnover rate through the sump is something that people often overshoot while designing their system. They often end up with a louder pump than needed.

It helps to know a bit about how a sump works and how equipment is affected by the turnover rate. This will help you to make the best decision about how much water needs to pass through your system.

The Purpose of a Sump

Many people coming into the hobby do so from the freshwater side of things. Take for example a freshwater cichlid tank with many fish. When you are dealing with a lot of fish and trying to keep the water clean, mechanical filtration does most of the work. Moving a lot of water through the filtration media is better in that case.

Mechanical filtration is only one part of a typical reef sump, and is sometimes left out completely. Most of the equipment present is not affected by the turnover rate.

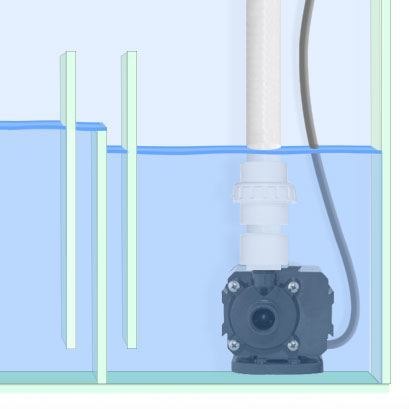

A sump on a reef tank acts more as a buffer-zone where water can move to a separate area, to be filtered and chemically processed. But it isn’t a matter of dirty water going in and clean water going back up to the tank. In reality, a skimmer or chemical filtration reactor will only process a fraction of the water that passes by it. The majority just moves right on past. So rushing a ton of water through the sump provides no benefit for the skimmer or reactors to work any better.

On a reef tank with an overflow and sump, the system needs enough turnover every hour.

What a rate of Turnover is trying to achieve

- Provide the system with a mechanism for gas exchange and the removal of solids over the overflow wier.

- Keep the water in the system a consistent temperature.

Create Flow in the tank– a better approach is to let powerheads in the tank create random flow.

What is the optimal Turnover Rate?

The 10X rule and the reasoning behind it

One thing you still hear quite frequently is that you need 10X or more times your system’s volume every hour when choosing a return pump. (An example would be a 90G system = 900GPH).

While the 10X rule is a nice round number, a turnover rate of 5X-7X of system volume per hour is often more than enough.

The 10X number has been around a long time. It’s hard not to think that most of the people who came up with it were basing it on the equipment that was available a few years ago. Older impeller-style powerheads were much weaker and less efficient than the ones we have today. Many of these newer pumps now have wide flow, and wavemaking capabilities.

Using some of these new propeller-style pumps means you don’t have to rely on the return pump to create random flow in the tank.

With most of the flow coming from powerheads, you don’t have to do anything fancy with the return line. Doing things like splitting the return outlet between multiple outlets generally isn’t necessary and can actually result in less flow than a single line. Same goes for using loc-line fittings to point the jet inside the tank. All this fiddling and over-plumbing really does is restrict the return pump output.

If you are trying to select a pump that is quiet and well suited to the job, just use a single outlet. Large enough pipe will also help to maximize the output of your pump.

More info about Creating Flow in the Reef Tank

More info about Creating Flow in the Reef Tank

Why you might want less turnover

By having a lower rate of turnover through the sump, there are a few advantages like:

- A smaller return pump can be used, which has a few advantages of it’s own. A smaller pump costs less to buy, and saves money in the long run by using less power. Not a bad idea for a device that runs 100% of the time. There is also a pretty big difference in both heat and noise between a 500GPH pump and a 900GPH one.

- You can stay well within the capacity of the overflow. A lower rate of return will also skim off a thinner layer of water passing over the weir. This decreases the chance of fish or debris going through the overflow teeth and causing problems at the inlets / standpipes

- When adding chemical additives or top-off water to the system, they will enter the display at a slower rate. This ensures changes to water chemistry don’t happen too fast. The theory is this is easier on the livestock. We’ll have to ask them if it makes much difference.

Surface Skimming, Agitation and how to decide on a turnover rate

The surface tension qualities of water mean that organics in the water are naturally drawn up to the top 1mm or so. This is one reason why it is so beneficial to drain water from an aquarium via an overflow. By allowing the surface to renew, you are helping to add oxygen to the water and remove waste through a natural process.

So having a good rate of turnover (more GPH through the return pump) will mean more water goes over the weir of the overflow every hour. So more stuff will make its way to the sump and skimmer. This “stuff” can be dissolved organics and solid particles in the water.

But how are you to know what "adequate surface skimming" really means? Well – it depends.

This is yet another area of reefkeeping that is up for contention. Most would agree that surface skimming is important, but it is hard to quantify. The difference in results between a coast-to-coast overflow and a conventional one are mostly anecdotal.

It would seem that surface renewal is important to an extent, but it’s importance is often overstated. Many overflows can provide decent surface skimming, provided the overflow teeth are designed right. Sometimes this can mean cutting out the existing teeth and replacing them.

The bottom line is you will find examples of successful tanks that have all types of overflows imaginable. Most of them can attribute success to good tank husbandry, not what the turnover rate is or how wide the overflow weir might be.

how many mph = 10x Turnover rate

42

That is the best answer to an unanswerable question that I have ever seen.